Welcome

HS-Luftfilterbau GmbH is your innovative supplier of a wide range of air filtration solutions for HVAC, supply / exhaust air treatment in Cleanrooms, Medical-, Pharmaceutical- and Processair applications.

Here you will find high-quality air filters for many applications.

From the standard air filter through to highly specified customer-oriented system solution, we offer you beside the complete range of usual standard products also fully tailored products according to your needs. All filter solutions we offer are manufactured in our production plants in Kiel / Germany.

News

We celebrate 50 years HS-Luftfilterbau!02.2024

We are at the start of a special year - 2024 marks the 50th anniversary of HS-Luftfilterbau GmbH. This is a milestone that underlines not only the longevity of our company, but also the innovations we have driven forward in the world of air filtration. Our journey began in 1974 when our founder, Dipl.-Ing. Harald Schuldt, decided to leave his successful career in the maritime industry to pursue new challenges. The choice fell on the then up-and-coming market of air filter technology - a decision

We are at the start of a special year - 2024 marks the 50th anniversary of HS-Luftfilterbau GmbH. This is a milestone that underlines not only the longevity of our company, but also the innovations we have driven forward in the world of air filtration. Our journey began in 1974 when our founder, Dipl.-Ing. Harald Schuldt, decided to leave his successful career in the maritime industry to pursue new challenges. The choice fell on the then up-and-coming market of air filter technology - a decision

that was to lay the foundation for half a century of success.

From humble beginnings on the basement steps of the family home to our current status as a leading manufacturer in the air filtration industry, we have always emphasized innovation, quality and meeting specific customer needs. Our production facilities have expanded from Flintbek to Kiel, Germany and beyond to Bangkok, Thailand to meet global demand.

Our focus has always been on being at the forefront of technology, as evidenced by our specialization in HEPA filters and custom designs, such as for nuclear technology. We pride ourselves on being pioneers in the development of new manufacturing processes that offer unique benefits to our customers.

Today, under the operational management of the second generation through Malte Schuldt, we not only look back with pride on what Harald Schuldt has achieved, but also look to the future with confidence. The challenges of the present, particularly with regard to sustainability and energy efficiency, are driving us to further focus our innovative strength and develop next-generation air filter solutions.

In this anniversary year, we look forward to presenting new breakthroughs in the field of air filtration. We invite our customers and partners to join us on this exciting journey. Follow us on our website and social media for the latest news and updates.

|

a view in the production 1984

|

|

new building 1992

|

|

expanded and renovated 2018

|

New production line for temperature resistant compact & HEPA filters05.2023

We are constantly investing in the expansion of our capacities and the improvement of our products and services. A key aspect of our new production line for compact and HEPA filters is not only the fact that we can assemble completely new types of filter media for extremely demanding filtration tasks. The new plant complex also gives us new options in the field of temperature-resistant filters.

We are constantly investing in the expansion of our capacities and the improvement of our products and services. A key aspect of our new production line for compact and HEPA filters is not only the fact that we can assemble completely new types of filter media for extremely demanding filtration tasks. The new plant complex also gives us new options in the field of temperature-resistant filters.

From now on, we can produce compact filters (HS-Mikro Pak) as well as HEPA and ULPA filters cost-effectively with temperature resistance up to 120°C.

Thanks to our new ABS plastic filter frames, even the more temperature-stable variants are fully incinerable and can thus largely be put to an energetic use (i.e. waste incineration) after use without any problems, as these products can be made completely metal-free. ABS plastic frames can replace steel and stainless steel filter housings almost everywhere. This saves operating costs and facilitates disposal.

HS-Inferno: keeps Pandora's box tight!02.2022

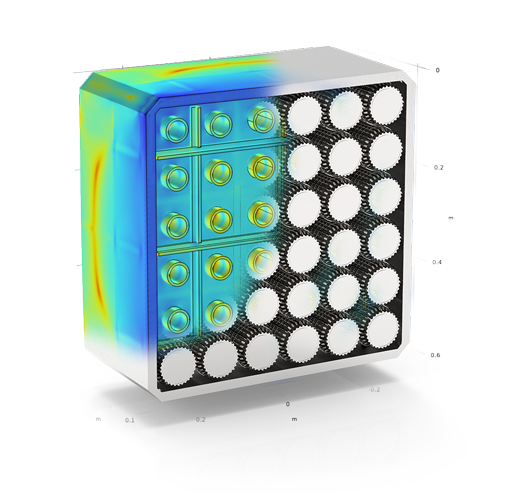

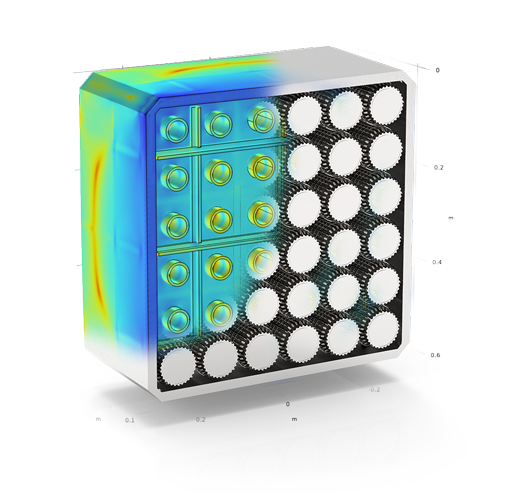

Process risks are not unavoidable, especially in complex applications with chemically and/or radioactive substances. If Murphy's Law occurs, pressure must be released from the containment in a controlled manner in an emergency or, in the worst case, fires or even explosions occur. In these cases, there is an acute contamination risk for the environment. The release of toxic and/or radioactive aerosols must be avoided at all costs by controlled pressure release. For this case, a HS-Inferno filter system is a risk minimization solution.

HS-Inferno offers ideal properties to be prepared in case of an emergency. Specially sintered stainless steel filaments serve as filter media to provide a filtration efficiency performance in the range of >99.95% MPPS i.e. ISO 29462 35H resp. EN 1822 H13 even in case of explosive pressure surges and temperatures above 600°C. The welded stainless steel construction can be designed either as a replacement filter element for extreme processes or as disposeable single use duct-housing solution for emergency cases.

We perform thermal simulations to evaluate the individual designs to avoid uncontrolled deformation and leakage at high temperatures and pressures during operation or in case of emergency.

HS-Inferno can be fabricated in standard filter element sizes e.g. 610x610x292 mm , but also in other process specific designs. Our engineers will design the solution for your individual process requirements.

We are at the start of a special year - 2024 marks the 50th anniversary of HS-Luftfilterbau GmbH. This is a milestone that underlines not only the longevity of our company, but also the innovations we have driven forward in the world of air filtration. Our journey began in 1974 when our founder, Dipl.-Ing. Harald Schuldt, decided to leave his successful career in the maritime industry to pursue new challenges. The choice fell on the then up-and-coming market of air filter technology - a decision

We are at the start of a special year - 2024 marks the 50th anniversary of HS-Luftfilterbau GmbH. This is a milestone that underlines not only the longevity of our company, but also the innovations we have driven forward in the world of air filtration. Our journey began in 1974 when our founder, Dipl.-Ing. Harald Schuldt, decided to leave his successful career in the maritime industry to pursue new challenges. The choice fell on the then up-and-coming market of air filter technology - a decision

We are constantly investing in the expansion of our capacities and the improvement of our products and services. A key aspect of our new production line for compact and HEPA filters is not only the fact that we can assemble completely new types of filter media for extremely demanding filtration tasks. The new plant complex also gives us new options in the field of temperature-resistant filters.

We are constantly investing in the expansion of our capacities and the improvement of our products and services. A key aspect of our new production line for compact and HEPA filters is not only the fact that we can assemble completely new types of filter media for extremely demanding filtration tasks. The new plant complex also gives us new options in the field of temperature-resistant filters.